cable tray roll forming machine factory and suppliers Gihua

(2)leveling for better punching then feeding to punching machine (3) roll forming machine (4)cut-off device. (5)finished profile, customer could change different mold to achieve different product (6)controller . comparing with traditional cable tray processing: Select the right sheet metal, cutting; Punching; Smooth grinding; Bending

Cable Tray Machine, Special Machine, Jupiter Roll Forming Pvt. Ltd.

A perforated cable tray roll forming machine is an essential equipment for manufacturers of cable trays used to support and protect electric cables, wires and

Customized Cable Tray Roll Forming Machine Wuxi TUT Machinery Co.,Ltd

Download the Temu App and start saving more today! Unleash incredible deals and coupons. Discover unbeatable deals and discounts on the Temu App. Download Now & Save Big!

Automatic Colorful Outdoor Perforated Cable Tray Roll Making Forming

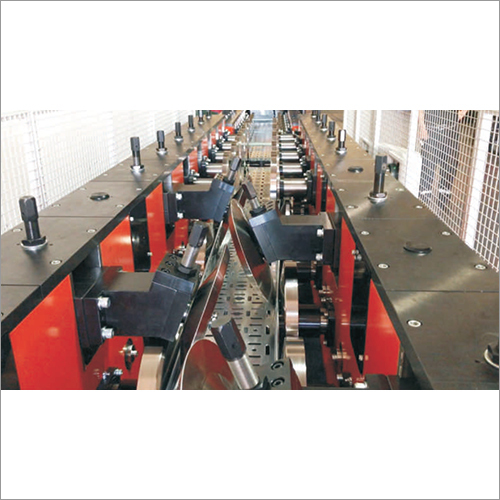

The Cable Tray Roll Forming Machine is an advanced industrial device specifically designed for efficient production of cable trays. With precision and speed, this machine creates consistent dimensions and smooth finishes, meeting industry standards. Its automated operations streamline production, reducing labor costs and improving productivity.

cable tray roll forming machine cable tray making machine " LOTOS

The cable tray roll forming machine is a non-standard customized production assembly line, which can form the cable tray at one time. The main forming machine has adopted a double-cantilever combination adjustable form, without changing the roller when adjusting the specifications of the products, which means that a set of rollers can complete the formation of a cable tray with any specification.

Automatic Colorful Outdoor Perforated Cable Tray Roll Making Forming

China leading metal roll forming machine manufacturer, great reputation. Customized design, competitive price. 20+ Years of experienced supplier

Best Cable Tray Roll Forming Machine Manufacturer and Factory Raintech

3. The roll forming craft is made by the special Germany cold roll forming program COPRA; the craft is also made the FEA analysis and check. The structure of the rollers is combined, so the line speed difference and resisting force of roll forming is small. The sheet is easy to feed. All these assure the accuracy and stable of the roll forming.

Cable tray roll forming machine. YouTube

cable tray roll forming machines 3 Types of Cable Tray Roll Forming Machines. There are two main types of cable tray roll forming lines: C-Type Roll Formers. Produce U-shaped cable trays with open top; Trays have inwardly bent edges for strength; Allows mounting trays on wall or ceiling; C-trays provide easy cable access through open top

100600 Mm Adjustable Cable Tray Roll Forming Machine With Long Life Time

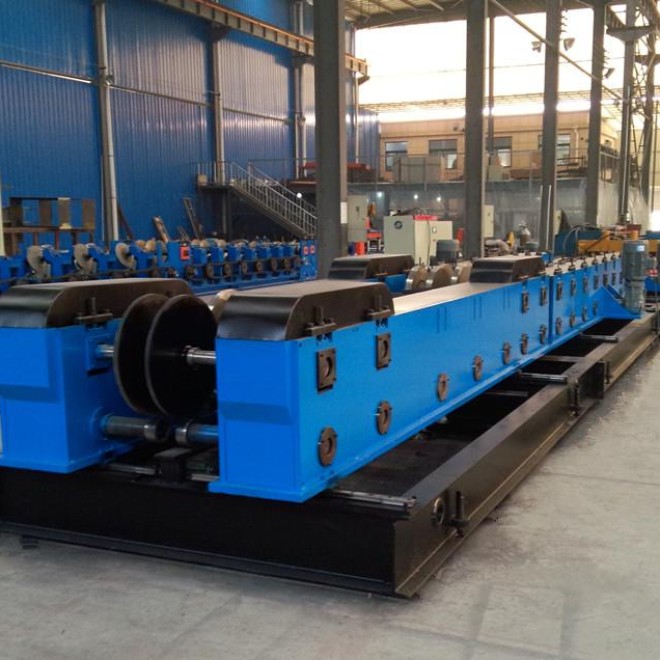

PRODUCTION DESCRIPTIONA This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including compute.

Cable Tray Roll Forming Machine Taicang Global Machinery CO., Ltd

ROLL FORMING MACHINE Cable Tray Roll Forming Machine Rolls Machinery, with over 17 years of expertise, is a leading manufacturer of Cable Tray Roll Forming Machines. Our ISO 9001:2015 certification attests to our commitment to quality, precision, and efficient machinery. We proudly serve clients in more than 40 countries. With…

Linear cable tray roll forming machine

New and Used Roll Formers insights. There are 65 Roll Formers for sale in Australia from which to choose. Overall 39% of Roll Formers buyers enquire on only used listings, 61% on new and 5.68% on both new and used Roll Formers items.Buyers usually enquire on 1.81 different Roll Formers classifieds before organising finance.

Strut Channel Steel Cable Tray Roll Forming Making Machine

A heavy duty cable tray roll forming machine is an essential equipment for electricians and electrical contractors to create customized cable trays. This guide provides a comprehensive overview of heavy duty cable tray roll forming machines, including working principles, types, materials, design, customization options, suppliers, installation, operation, maintenance and more.

Auto Adjustable Cable Tray Roll Forming Machine For 100 300mm Width

ET5 Cable Tray 150-600mm width, 78mm cable laying depth, 85mm side wall, 3m lengths. EzyTray Cable Tray 150-600mm width, 40mm cable laying depth, 45mm side wall, 3m lengths. CT Cable Tray 75-600mm width, 20mm side wall, 2.4m lengths, perforated bottom. High Sided CT Cable Tray

JKR Cable Tray Roll Forming Machine YouTube

otherwise, Its last version of a multi-size cable tray roll forming machine can do various length sizes and with different heights. It's suitable for the thickness of 1.2-2 mm. Lotos has long experience on different cable tray roll forming machines, with different punching designs. Nowadays the different industry manufactures, inquiry.

Cable Tray Roll Forming Machine Manufacturer,Supplier,Exporter,Gujarat

Cable Tray Roll Forming Machines can be broadly classified into two types- those that use a single roll form and those that use multiple rolls. The single roll type machines use a large diameter, flat sheet steel sheet as the forming surface. The sheet is fed into the machine on one side and emerges on the other side with the desired.

Linear cable tray roll forming machine

The cable tray produced by the forming machine is suitable for: R Autralia Cable Tray It can be rapid formed and automatically discharged directly. The production is very convenient and fast, and is common in all industries.